KHS Innofill DRV Filling System Holds Pioneering Position

Comprehensive range of new features integrated into the filling system

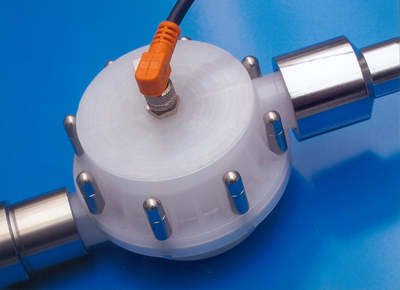

With a comprehensive range of new features, the success story of the Innofill DRV plastic bottle filler from KHS continues! The Innofill DRV not only operates with electromagnetic inductive flowmetering but now also provides volumetric metering for beverages with low or no conductivity. In addition, instead of just processing various plastic bottles with an identical neck diameter, now an entire range of plastic bottles with two neck sizes can also be effortlessly handled. What's more, the materials used for membranes and seals on the Innofill DRV system can now be optionally provided as newly developed, aroma-resistant elastomers. The computer-controlled, volumetric Innofill DRV filling system offers maximum flexibility. From the 0.1-liter to the 5-liter plastic bottle, this filler is capable of processing all conceivable bottle shapes and sizes. Filling capacities go up to 72,000 plastic bottles per hour. The Innofill DRV is available in a number of different versions. In full accordance with customer requirements, the modified machine can cope with a number of different filling processes, such as classic pressurized filling on its own, classic pressurized filling combined with pressureless filling, classic pressurized filling plus triple-chamber pressure filling and pressureless filling or single-chamber pressure filling in conjunction with pressureless hot filling. This creates an extremely wide spectrum of use for all conceivable eventualities. The Innofill DRV filling process uses swirlers and is thus particularly hygienic and exceptionally gentle to the product. Another very recent feature is that impeller flowmetering can now also be used in addition to electromagnetic inductive flowmetering. Impeller flowmetering is based on the volumes of liquid transported in the impeller areas in conjunction with the speed of rotation of the impeller. Signals are transmitted without contact to a sensor that derives the fluid flow rate from the measurement signals. The impeller flowmeter extends the Innofill DRV's range of use in full keeping with industrial requirements. Thanks to this instrument of measurement, beverages with a very low or even no electrical conductivity can be filled on the Innofill DRV. This caters for a growing consumer demand for demineralized water, for instance, that does not have a significant measurable level of conductivity. Guaranteeing top standards of hygiene was another major factor in the development of the impeller flowmetering system. The new system of measurement thus consists exclusively of extremely heat-resistant materials that permit sanitization and sterilization at temperatures of up to 120°C. If plastic bottle types with two different neck diameters are to be filled, the Innofill DRV is now also able to do the job! If a different bottle neck diameter is scheduled, filling valves can be easily changed by quickly replacing the neck ring holder without using any tools. A further positive aspect of this new feature is that the Innofill DRV is not only able to fill non-carbonated beverages but also carbonated drinks in plastic bottles that have large-size, 38-mm bottle mouths, for example. KHS is also meeting the demands of the trade with the optional use of a new material made of aroma-resistant elastomers for the aseptic membranes and seals used in the filing system. This helps to shorten sanitizing cycle times during product changeover even more. And what's more, the production schedule no longer has to make allowances for the taste intensity of the beverages to be bottled.