Tethered caps: launching you to market on time and in full keeping with all directives

The EU directive on tethered caps will come into effect in July 2024. It states that closures on non-returnable PET bottles holding up to three liters must be firmly attached to the container. The aim is to recycle the caps together with the bottles and thus avoid environmental pollution caused by loose closures. KHS will help you to find a solution that suits your requirements and is ready for production when the directive comes into force. What is important here is that you reserve an installation date with your service representative now, for the current market challenge lies in the uncertain supply of materials and energy.

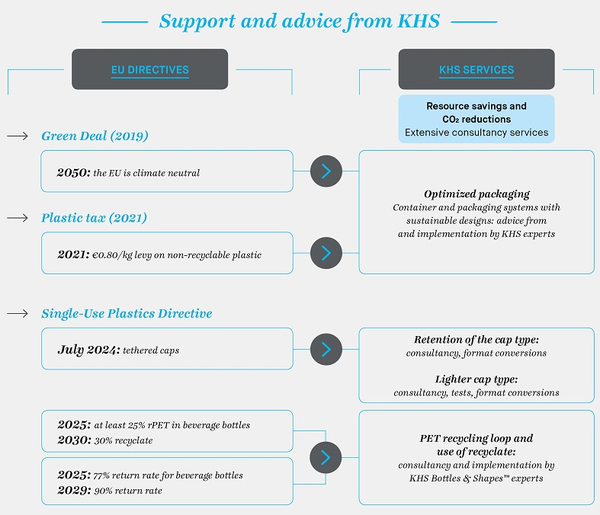

This requirement is part of the European Union’s Single-Use Plastics Directive. It lays down further regulative steps that are to be instigated by 2030 to recycle non-returnable PET beverage bottles and their individual components within the EU. The aim is to continue to save on resources and cut carbon emissions. KHS offers a number of advisory approaches here that are designed to suitably prepare you for the coming directive (see graphic).

Tethered caps are now one of the first measures to enter into force through national law in the member states on the same appointed date (July 3, 2024). Beverage producers thus have to adapt their production processes so that the new closures remain attached to the bottles even when open. This inevitably leads to technical adjustments to the filling system that we would be happy to discuss with you now so that you are well prepared for the change in time.

We know from discussions with our customers that they wish to aim for a future-proof standard that takes consumer drinking habits into account and at the same time can be implemented with technical efficiency. This calls for a dedicated examination of the cap, for despite container threads being identical the cap can display major differences that have a direct impact on the scope and duration of the conversion.

In addition, owing to the high energy and raw material prices for rPET and HDPE, lots of customers are asking themselves if they should just aim for a simple conversion or seize the new legal requirements as an opportunity to not only save weight in the long term by applying a lighter closure but also cut down on the amount of material used for the thread and bottle itself.

Further reading

Forming an attachment (khs.com)

Thinking outside the box: KHS’ team of experts provides extensive advice on non-returnable PET bottles with tethered caps.

Learn moreTesting closure options and assessing added value

Depending on the variant of closure, you can test the caps on your existing line in advance and use the time now to draw up the technical specifications in good time. In other cases, however, differences in cap despite the container having the same thread can mean that later technical adaptation of the units on the filling line is more complex than originally thought.

In this phase particularly, precise and above all timely clarification of all requirements is essential for both you and us for later adaptation of your filling line to tethered caps. “The process of selecting a suitable closure is complex and can take months depending on the specific use case. Accordingly, the implementation itself requires early planning. It’s thus important to clarify requirements now so that we can reliably realize the directive for our customers,” says Arne Wiese, expert Bottles & Shapes consultant for caps, threads and container design at KHS.

As experts in turnkey filling and packaging systems, we always focus on the complete line as a matter of principle. Together with you, our experts from Bottles & Shapes analyze your [r]PET beverage container to save resources, cut carbon emissions and at the same time ensure the availability of your production line in the long term. We also provide a wide range of packaging systems for secondary packaging, with which you can also process your [r]PET packs reliably, efficiently and in a way that is gentle on resources.

Finding individual and sustainable approaches together

Regardless of whether you would like some initial advice or already have concrete ideas: simply get in touch with us – we will be happy to be at your service and develop the right solution with you and for you!

Your contact

Advice on conversions and added value:

Armin Wille

KHS Group

Phone: + 49 231 569 10284