Focus on Stability, Sustainability, and Cost Reduction

New KHS development produces shrink packs without shrinkage holes

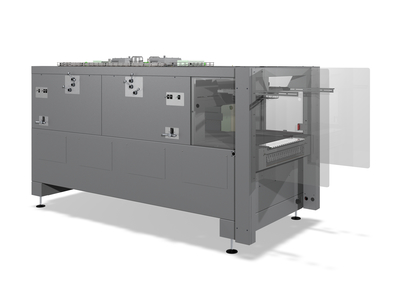

In our modern day and age the market demands robust yet attractive secondary packaging which is cheap to produce and also pays more than just lip service to the aspect of sustainability. With this firmly in mind, KHS has now engineered a new development in the field of shrink packing; using a specially constructed manipulating unit installed in the KHS shrink packer, it's now possible to wrap products in film packs that do not have shrinkage holes. This option is particularly interesting when larger product formations are to be shrink wrapped, such as packs of 24 cans. The clear advantage here is that the new system more or less eradicates the danger of containers becoming displaced within the shrink pack, an annoying problem that can occur during inline conveying, at the point of sale, or from handling by the consumer. The packaging can even be carried by a handle attached to the side without the containers becoming displaced. This also means that film packs without shrinkage holes are ideal for transporting packaged products. Another benefit of shrink film packs being formed without shrinkage holes is the potential saving this entails. The cardboard trays or pads that were previously needed to keep large-format shrink packs stable are no longer required with this new option. Taking the 24-can shrink pack by way of example, about 10% more film is needed per new shrink film unit. Set against this is a saving of about €0.05 per shrink pack if no pad is used – or approximately €0.10 if the shrink pack no longer needs a cardboard tray. In addition to the savings potential this reduction in materials holds, logistics costs can also be cut. These include those for the delivery and storage of trays and pads; the effort involved in the extensive handling of trays and pads and the feeding of tray blanks or pads into the packaging machine by an operator also becomes redundant, thereby also increasing the availability of the packaging machine. Added to this is the fact that the environment considerably profits from the use of fewer packaging materials. As the shrink pack is now stable, it would also be feasible to apply a carrying handle and include tear-off sections at various points and in various designs so that the packaged goods can be easily removed. Companies in the beverage, food, and non-food branches of industry who process large-format shrink packs are all destined to benefit from this innovation. The manipulating unit needed to form shrink packs without shrinkage holes can be procured as part of a new investment or retrofitted into existing KHS shrink packer concepts.