KHS technology part of the company philosophy

Khmer Brewery in Cambodia again invests in a KHS turnkey canning line

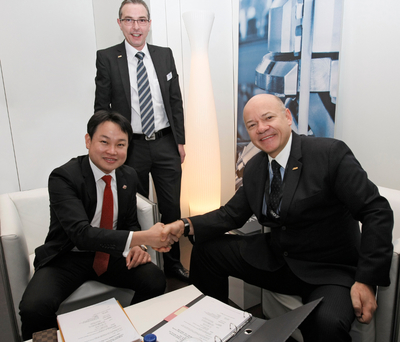

Khmer Brewery in Cambodia again invests in KHS technology. Peter Leang, senior executive vice-president of Khmer Brewery, recently signed a contract for delivery of a turnkey canning line which can output 60,000 0.33-liter cans per hour. Leang states, "There are two definitive reasons for investing in a further KHS line. The first is that we're extremely satisfied with KHS machinery. The second is that KHS gives us excellent customer care and is always on hand when and if service is required." Khmer Brewery, opened at the end of 2011, currently operates three KHS turnkey systems: a canning line, a glass line, and a keg line. With its new investment the brewery will be able to fill and pack up to 90,000 0.33-liter cans per hour. Canned beer is popular in Cambodia mainly because beer in cans is easy to transport and the people here are familiar with this type of container from imported products. Typical for the country, therefore, the amount of beer sold in cans accounts for 85% of Khmer Brewery's total sales. With the realization of a planned boost in sales, the new investment had to materialize fast. In the first half of 2012 Khmer sold 300,000 hectoliters of beer, with this figure crossing the 750,000-hectoliter mark at the end of this year. In 2013 Leang is reckoning on selling around 1.3 million hectoliters of the beverage. His aim is to push sales figures up to four million hectoliters by 2017, thus becoming top of the list of Cambodian breweries. Leang states, "Our strategy of providing the people of Cambodia with only the best quality in the form of our Beer Cambodia brand is paying off. This is reflected in our high sales growth. In the future, too, we'll continue to act as the brewery from Cambodia for Cambodia." The heart of the recently ordered KHS turnkey canning line is an Innofill DVD filling system with over 76 filling stations. Cans are fed to the filler following fully automatic depalletizing by an Innopal AS1H and conveying through the vacuum bridge. The principle of electromagnetic inductive flow metering is used here to achieve maximum fill level accuracy. Deviations in can capacities supplied by various manufacturers are therefore no longer a matter of concern. The Innofill DVD features smooth product passages throughout the machine from the ring bowl to the filling valves. Aseptic membrane and sealing technology is used in all Innofill DVD filling valves and in all other channels and routes exposed to the product. Leang smiles. "What we like most about the Innofill DVD besides its ultra-precise filling is the extremely low-oxygen filling process. This enables us to perfectly preserve our outstanding beer quality." Leang considers another main aspect of quality to be KHS' PU control utilized in the Innopas PISC pasteurizer. With it over-pasteurization is reduced to a minimum and high flavor stability ensured even if multiple stops occur. As with its first investment Khmer Brewery has opted to pack cans into cartons on the new canning line. For this purpose there are two Innopack CA carton openers placed upstream of the Innopack PPZ packer. These set up folded cardboard box blanks, fold in the bottom flaps, and glue them with hot melt. An Innopack CV installed after the can cartoner ensures flawless glue application and perfect carton sealing. An Innopal PBN1 then palletizes the cartons with level compensation and automatic layer formation. Says Leang, "In KHS we've found the trusted partner we'd like to shape the future with. We feel we're in the best of hands on all counts." In Cambodia, drinking beer is in – not just because Cambodians like beer but because the consumption of beer also implies a certain status. Observers anticipate annual rises in beer sales on the Cambodian market of between 15 and 20%, based on a present per capita consumption of 18 liters of beer per annum.