BrauBeviale 2024: holistic line concept in focus

The countdown has started: not long now and the exhibition center in Nuremberg, Germany, will become one of the key venues for the beverage industry. From November 26 to 28 BrauBeviale is again opening its doors to suppliers and trade visitors from more than 100 different countries. As your reliable partner and one of the biggest exhibitors at the show, we want to seize this opportunity to show you our latest technologies and systems and solutions.

Our exhibition concept this year focuses on our pioneering filling technology, extensive inspection systems and the latest developments on our bottle washers. We will also be presenting our new generation of Plasmax machines and broad range of services. We heartily invite you to come and see us at our show booth! Take the chance to find out how we can optimize your production processes together with you.

BrauBeviale 2024

Opening times for visitors:

November 26–27, 2024, from 9.00 am to 6.00 pm

November 28 from 9.00 am to 5.00 pm

BrauBeviale

Messezentrum

90471 Nuremberg

Germany

Find us here:

Hall 8

More information on the BrauBeviale website.

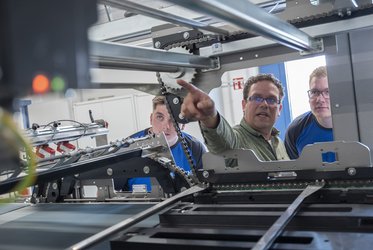

At BrauBeviale we’d like to enable you to experience close up what partnership on an equal footing really means to us. For we know what moves and affects both you and the industry. With us, discover how we’re integrating sustainability, efficiency and digitalization into all of our comprehensive and durable systems and solutions. We will be showcasing these under the headers of circular packaging, reliable services, line efficiency and smart operations. Our team is ready and waiting to give you detailed insights into our plant engineering.

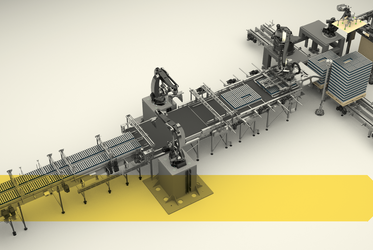

Flexibility, hygiene and reliability all in one: come and explore our successful compact Innofill Can C canning model. Together with the powerful seamer unit manufactured by Swiss engineering company Ferrum, it achieves an output of up to 60,000 cans an hour. Our filler can be perfectly integrated into medium-capacity beverage lines, particularly in conjunction with our inspection technology that has been continuously expanded over the last few years. This includes, among other units, the Innocheck MMS machine management system that localizes and assesses faulty filling valves and closure elements, the newly-developed Innocheck FHC fill level checker that monitors fill levels by X-ray and the Innocheck ECI empty can inspector. The latter examines empty cans for foreign bodies and damage. Furthermore, an extension also retrofittable on existing lines allows previously undetected blind spots to be identified. With these systems and solutions that have proved themselves on the market many times over, we’re not only improving the quality of your production but also increasing the safety and efficiency thereof.

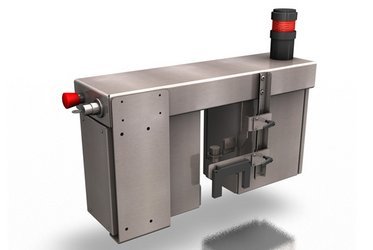

One solution to the demand for circular packaging is provided by our unique latest-generation InnoPET Plasmax technology. This coating process for PET containers covers the insides of plastic bottles with an ultra-thin layer of glass. Available as a single machine or blocked with a stretch blow molder and/or additional filler unit, it gives you highly effective product protection that unifies optimum quality, freshness and shelf lives with 100% recyclability by type.

In addition, through our ConnectApp Guide we’d be happy to introduce you to our portfolio of digital services and explain how our consultancy and many other services ensure that your lines run smoothly and trouble-free. Come and visit us at our booth to see how we’re committed to creating a sustainable and efficient future for the beverage industry.

We’re looking forward to meeting you!