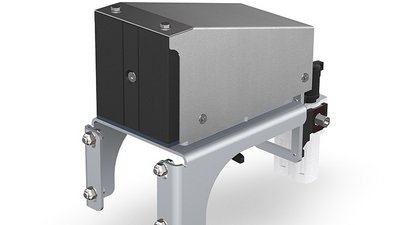

Innocheck ECI empty can inspector

Good to know

Only the best for your customers: our Innocheck ECI inspects your empty cans for foreign bodies and damage quickly and thoroughly, thus ensuring the quality of the cans for filling. It does not matter whether the cans are intended for use in the beverage, food or non-food industries. The empty can inspector checks the inner side wall and the base area as well as the top edge of the can. If it establishes the presence of deformation, cracks, contamination or other defects, the Innocheck ECI ensures that the can is correctly channeled out of the system to enable trouble-free filling and trouble-free conveying. With an inspection capacity of up to 132,000 cans/h, the machine moves in the high-performance range and yet satisfies the most demanding quality requirements without difficulty.

Well thought out

Cameras equipped with innovative lighting techniques inspect every incoming can quickly and precisely. The images are evaluated immediately by means of modern, high-resolution KHS image processing systems. At the same time, innovative software algorithms ensure the exact assignment and sorting of evaluated cans. The system can be expanded by fitting an additional camera in the compact structure of the optical unit in order to optimize detection accuracy.

Convincing

- The latest cameras ensure reliable detection of even the smallest amount of soiling and damage to empty cans

- Innovative lighting provides highest primary image quality

- Simple cleaning and maintenance thanks to compact, hygienic design

Sustainable

- Save maintenance costs thanks to the use of maintenance-free LED lighting

- Innovative software concept provides maximum future-proofing