New KHS Dosing and Blending System with Plenty of Added Bonuses

Innopro Paramix C quenches the beverage industry's thirst for innovation

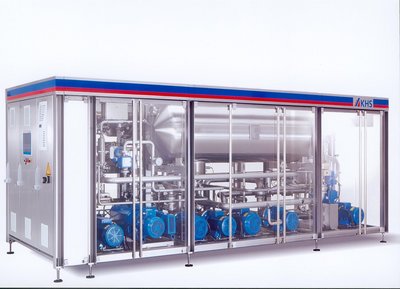

With its new Innopro Paramix C dosing and blending system, KHS is making provision for the beverage industry's strong desire for innovation the world over. At the same time, the Innopro Paramix C is also meeting a greater number of comprehensive industrial requirements. The new dosing and blending system is now able to handle extremely fast product changeovers with minimum product loss, providing a maximum level of automation and minimum operator involvement. In addition, the Innopro Paramix C now perfects communications with upstream and downstream KHS systems while also reducing the amount of space required for the new plant engineering. The three-component, Innopro Paramix C dosing and blending system produces still and carbonated beverages in a continuous process. It can also be expanded as required to include a fourth or fifth dosing segment. The capacity of the Innopro Paramix C ranges from 4,000 to 74,000 liters per hour. Both the deaeration and finished beverage tanks of the Paramix C are installed horizontally, thereby reducing the amount of space needed for the system and creating a number of added technological bonuses. The Innopro Paramix C fits into one shipping container and can be transported as one unit with all functional mixer modules fully integrated. Once the compact unit has arrived at the beverage plant, all the customer has to do is connect up the various supply lines and production can get going! As opposed to conventional systems, this considerably reduces the time needed for machine commissioning – in full keeping with the Plug & Produce principle. The Innopro Paramix C can also be supplied with an optional glass housing. This has the advantage of providing maximum hygiene, even more protection for the machinery, and improved soundproofing. The Innopro Paramix C deaerates, blends, and carbonates. The first step in the process is to deaerate the water according to the principle of two-stage vacuum spray deaeration. As opposed to setups that use a vertical deaeration tank, the horizontal deaeration tank and method of spraying distribute the liquid particles over a greater surface area. This aids successful deaeration considerably. The Innopro Paramix C reduces the residual oxygen content in the water to less than 0.3 milligrams per liter. Precision mass flowmetering takes place in the syrup pipe train upstream of the mixing pump. By selecting this form of measurement, when the product is changed even diluted syrup phases can be automatically and accurately detected. This enables the mixing ratio of syrup and water to be adjusted in such a way that after blending using the KHS minBriX process the desired product is produced exactly as required in the given quality. This results in diluted syrup phases no longer being discarded – as has been the case up to now. What's more, there is practically no syrup loss. Product changeover has also become extremely quick, which in turn increases the overall efficiency of the filling and packaging line. The Innopro Paramix C has standard syrup-to-water blending ratios of 1:3 and 1:9. An extended blending range of from 1:1 to 1:10 is also feasible. The dosing accuracy for syrup is around 0.05° Brix. During the carbonation process in the Innopro Paramix C, KHS' special carbonation nozzle ensures that the carbon dioxide is optimally distributed and bonded. Innopro Paramix C's standard carbonating range lies between 2 and 9 grams of carbon dioxide per liter. This can be extended to cover a range of 0.5 to over 9 grams of CO2 a liter if required. The advantage of the horizontal finished beverage tank is that any bubbles of undesired gas that may remain in the product quickly rise to the larger product surface. This is yet another aspect which, together with the deaeration and carbonating procedure that has been planned right down to the last detail, also brings about a clear increase in filling system efficiency, thanks to the minimized amount of microbubbles in the product. KHS defines the Innopro Paramix C and a downstream KHS filling system as a one-process technology unit and regulates the programming and controls accordingly. In the manufacture of products, the Innopro Paramix C thus directly orientates itself to the output of the KHS filling system. The Innopro Paramix C operates fully automatically. Both production and cleaning processes are continuously synchronized with the KHS filling system. If the product is to be changed, all the authorized machine operator has to do is simply select the new recipe on screen. All in all, the Innopro Paramix C is a dosing and blending system that fully meets the demands and requirements of the beverage industry. And on top of it all, the Innopro Paramix C is also a visual highlight that is clearly destined to make its mark in the beverage sector worldwide in the future.