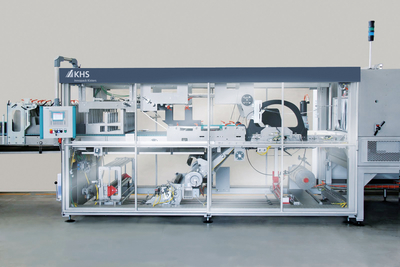

Optimized KHS Innopack Kisters Primus SP shrink packer with many benefits

With the Innopack Kisters Primus SP KHS is giving the beverage, food and non-food industries a shrink packer in the low capacity range which has just had a thorough makeover. The optimized machine now includes many extra features from the high performance range and has a much broader spectrum of benefits than the previous version. Additional pluses include greater ease of operation, an improved design and greater attention paid to the aspect of sustainability.

The Innopack Kisters Primus SP operates at up to 35 cycles per minute, perfectly complementing the KHS range of Innopack Kisters shrink packers to include a low capacity machine. As in the other series Primus SP machines are also cube-shape in design. More space within the machine means that there is better access to the individual components. Generously proportioned sliding doors with polycarbonate panes give an excellent view of the inner workings of the shrink packer – even during production. The new construction has an open, hygienic design. Despite being extremely simple to operate, the shrink packer is still compact; with a length of 9,700 mm (including the shrink tunnel) and a width of 1,950 mm, it can also be easily integrated into existing lines. The Innopack Kisters Primus SP has also had an overhaul regarding its control technology, with the system now equipped with a Siemens S7 controller. The machine has a total of four drives with a main drive, tunnel drive, film reel drive and feed conveyor drive and identical servomotors are used for all function units. In the old Primus SP series it was usual to have the switch cabinet under the shrink tunnel construction. In warmer climates especially the standard ventilation and cooling equipment used for the switch cabinet often exceeded its limits and additional or larger air conditioning units had to be installed. This is now a thing of the past. A welded tubular frame is used as a support for the shrink tunnel, with the switch cabinet placed next to the machine and therefore readily accessible. The Innopack Kisters Primus SP processes many different types of container, from the plastic bottle through the glass container to the can. Products and film are conveyed extremely gently, with product-dependent wrapping curves and an electronically controlled curve speed profile giving optimum film wrapping results. The shrink tunnel area utilizes variable hot air nozzle equipment and can be fitted with an optional energy-saving package for energy savings of up to 20%.