BrauBeviale 2023: moving into the future with sustainable customer systems and solutions

Partnership on an equal footing: this is what we’re finally – and literally – again looking forward to after the lengthy corona break at BrauBeviale which this year takes place from November 28 to 30 in Nuremberg, Germany. We’re delighted to again be able to live up to our motto of “your reliable partner” face to face: talks, discussions, advice, exchanges of mutual ideas, projects, informative and instructive exhibits – we’ll be on hand with all this and more as the second-largest exhibitor at one of the leading capital goods trade shows for the beverage industry worldwide. This is where you can meet suppliers and trade visitors from more than 135 different countries and together make a big impact.

During the three days of the exhibition, you’ll be able to gain insight into the entire beverage production value chain – from creative brainstorming through raw materials, technologies and components to numerous packaging options, accessories, marketing and services. As a special service you can also benefit from the digital platform for the beverage industry (myBeviale.com) that enables you to network and keep in contact with other experts and interested parties all year round – in full keeping with the concept of reliable partnership.

BrauBeviale 2023

Opening times for visitors:

November 28–29, 2023, from 9.00 am to 6.00 pm

November 30, 2022, from 9.00 am to 5.00 pm

BrauBeviale

Messezentrum

90471 Nuremberg

Germany

Find us here:

Hall 8

More information on the BrauBeviale website.

Do you have any questions about the trade fair, or would you like to make an appointment?

Then write to us at brau[at]khs.com.

Holistic support with sustainable and profitable added value

As an experienced and service-oriented partner, we naturally don’t consider your challenges and requirements individually or devise short-term solutions but instead always implement these strategically so that the best result can be expected in the long term. For us, this means that right from the very start we believe it’s essential to exchange ideas and information and that our partnership is by no means over once an order has been concluded. For at KHS, being a reliable partner is much more than just a slogan; it’s what we are to our customers each and every day.

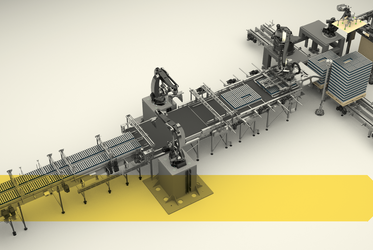

Together with us, find out at BrauBeviale what exactly is to be understood by this! The issues of sustainability, efficiency and digitalization we associate with this are mirrored in all of our areas of focus. In our circular packaging, reliable services, line efficiency and smart operations clusters we’ll be demonstrating our broad spectrum of economical and durable filling and packaging systems to you.

Convince yourself of our SmartCan filler/seamer block for cans that we’ve jointly developed in cooperation with Ferrum and that gives you great benefits when it comes to flexibility, efficiency and operation. In addition to the established canned beverages of beer and carbonated soft drinks, for some time now there’s been an ever stronger trend towards filling more sensitive products such as iced tea, plant-based drinks, juices, smoothies, near-water products or alcohol-free beers and mixed beer beverages into cans. Accordingly, beverage fillers’ hygiene requirements are also rising. We will present to you how our machines perfectly dovetail with those manufactured by Ferrum. Our can filler boasts an optimized hygiene concept and provides more flexibility, greater efficiency and simple operation.

At our booth we’ll also be featuring our Innokeg X washing and filling module and ECOSTAB beer stabilization system. Our exhibits in Nuremberg will show you just how we aim to realize the market demands of the future.

We look forward to your visit!

Blocked content

This YouTube video is blocked because you have not agreed to the YouTube service. By clicking the button you can change the cookie settings and play the video.

Discover our four focus topics

We want your systems to run as efficiently as possible – and produce maximum quality in the process. If you wish to ensure optimum beer enjoyment, our Innofill Glass DRS ECO is well worth visiting at the show: it has the lowest possible oxygen pickup during filling. At the same time, you also profit from considerably reduced CO2 consumption. Ask us to show you this leading market technology in practical operation!

A special evacuation and CO2 purging process for glass bottles first removes air – and thus oxygen – from the containers by vacuum during pre-evacuation. They are then purged with a precisely dosed amount of CO2. This makes the process highly efficient compared to the conventional methods commonly used to date that purge containers twice with the gas, for example. In this way, beer can be filled in an almost pure CO2 atmosphere so that it can pick up practically no more oxygen. High-pressure injection that foams the beer directly before the bottles are closed is also helpful as this displaces the tiny amount of remaining air from the bottle neck and under the domed crown cork.

The DRS ECO is distinguished by its lower energy consumption (which is reduced by up to 20%), with CO2 emissions even falling by as much as 50%. Come and see us and let us explain this process to you! We’re looking forward to your visit and will be pleased to address any of your personal questions and concerns.

As an experienced specialist for filling and packaging systems, we see ourselves as a turnkey supplier who finds it extremely important to provide its customers with tailored support. This is why we’ve developed an extensive training portfolio for you. This gives you the opportunity to learn from us in a number of different ways – from in-person events to webinars. During the pandemic especially we added a good number of digital formats to our range of services. Our current focus is on asynchronous or blended learning that allows you to continue training digitally – whenever and for as long as you wish – without us having to be present in person. After having successfully introduced this form of virtual training using the example of our can filler, at BrauBeviale we’ll be showing you further machines in the KHS canning line that you can learn to operate and service virtually. In the coming year, machines for glass and PET bottle filling are to be added to the program.

We’d be happy to advise you at the trade show and look forward to plenty of instructive and efficient training sessions!

We endeavor to not only work at the highest technical level but also provide you with the best possible customer service so that your KHS systems run without fault and give optimum performance at all times. This is why at KHS, the application of remote services is par for the course. We’ve established our ReDiS remote diagnostics system, for example, which we can use to provide you with fast, uncomplicated assistance should you have any queries regarding your KHS engineering. With this highly efficient method for the remote maintenance of your machines and systems through a VPN (virtual private network), we can offer direct advice to plant operators all over the world and support our service engineers at work on site.

Our Augmented Reality Service (ARS) is another form of remote assistance we offer. It helps to maintain the availability of your line(s) and saves you time and money should technical problems occur. We connect up with you virtually and, with the help of smart glasses, see what you can see on site. This enables us to quickly record and remedy all faults and sources of disruption. Even if faults prove more complex, our service personnel can examine the fault in detail, regardless of where they happen to be, and find a solution together with you through this audiovisual link.

We also offer a broad spectrum of other digital support options. For instance, through our new machine label with a QR code you can directly access the respective machine webpage on our customer portal that then immediately provides you with relevant information on the machine. In addition, with our Innoline MES (Manufacturing Execution System) and Innoline BLM (Basic Line Monitoring) products we offer modular, standard software packages that have been adapted especially for the beverage industry and provide a customized overview of the entire beverage filling process.

As an experienced specialist for beverage packaging, we attach great value to the continuous further development of sustainable systems and solutions. For this is what gives you the basic potential to create holistic circular packaging options, cut down on emissions and set yourself up for the future – issues that are becoming increasingly important to consumers.

Streamlined, sustainable material systems are among the key levers here – and these include allegedly minor components such as adhesive. These have a truly great impact: just a few grams of the same can replace all of the secondary packaging, as in the case of our special Nature MultiPack (NMP) universal adhesive. This results in a carbon footprint of just 4.4 grams of CO2 equivalents per pack. These small but extremely efficient dots of adhesive can join not just cans but also [r]PET bottles together, creating a pack that needs no secondary packaging whatsoever. The new adhesive can be used on practically any shape, size or material thickness of container without changing specifications for different batches of preforms having to be accounted for. The flexibility this lends the pack enables the forces applied to the same along the logistics chain to be compensated for, resulting in less damage. For consumers, the adhesive also has the advantage that it makes bottles even easier to handle and separate as it’s extremely elastic and thus peels off very easily – without damaging even lightweight bottles that have very thin outer walls, for instance. In combination with our new cardboard bottle clip carrying handle this produces a stable pack of [r]PET bottles, offering an alternative that’s gentle on resources in several respects.

We’d be happy to provide you with advice and help you develop and implement circular packaging systems!