KHS line heater for even more PET bottle material savings

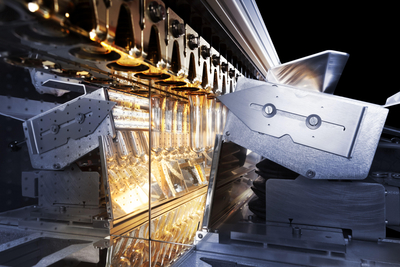

The beverage industry wants ever lighter PET bottles which also remain stable and ensure the quality of their products. With its line heater KHS is taking another important step towards reducing bottle weights – while maintaining first-class bottle quality. The line heater is a module that is usually integrated into the rear heater area of a KHS stretch blow molder. On request the system can also be quickly retrofitted with little effort. All the necessary connections are provided and the relevant interfaces standardized. Energy-saving shortwave infrared radiation The InnoPET Blomax Series IV stretch blow molder uses near infrared (NIR) to heat preforms. Only shortwave infrared radiation with an especially high energy density is used. With NIR the heat penetration of the preform wall is extremely intense – a feature further enhanced by feeding the preform through a closed heating chamber with all-round reflection. This enables an ideal heating profile to be applied to the preforms while saving energy. During the controlled heating process the neck area of each preform is shielded. This is because this area may not be heated to prevent any possible deformation of the neck, enabling the PET bottles produced after the heat-up phase to be securely closed. As the neck area is so critical, there is an extremely temperature-sensitive zone directly below the support ring. This must be protected against heat towards the neck yet ideally heated with the utmost precision towards the preform body in order that the PET material in this area can be perfectly stretched. The use of the line heater makes exactly this possible. Precisely focused linear heat ray The line heater is integrated into a specially designed module which has a reflector. The module has a parabolic mirror which produces a defined, precisely adjustable ray of heat. This permits focused heating of the critical area beneath the support ring without affecting the sensitive neck area. In this way, the additionally heated PET material can now be transfered to the bottle body during the stretching process. This means that lighter preforms can be used in the manufacture of PET bottles. When the product is changed over, the line heater can be quickly and easily adjusted. Annual savings greatly exceed investment costs If we assume that on the line heater 0.5 grams more PET material per bottle body is used than was the case to date, at an annual production of 100 million bottles this means that approximately 50,000 kilograms less material in total is used. At an assumed PET price of €1.40 per kilogram €70,000 is saved each year. This amount is many times more than the cost of investment in a line heater.---

KHS GmbH is one of the leading manufacturers of filling and packaging systems for the beverage, food and non-food industries. Headquartered in Dortmund, Germany, the company has over 4,500 employees worldwide.