Traditionally Innovative

Rhodius Mineralquellen points the way to the future

Investment in a new KHS keg line keeps hospitality trade highly satisfied

Günter Unkrig*

Wolfgang Augel**

* Director, Central European Business Area, KHS AG, Dortmund,

Phone: +49 (231) 569-1602

** Sales Germany, KHS AG, Dortmund,

Phone: +49 (231) 569-1635

From flake white to grinding tools to Pepsi

The origins of the Rhodius company go back to the year 1827. The enterprise started out by manufacturing flake white, a colored pigment used as an underpainting layer for oil painting. Later activities concentrated on the production and sale of carbon dioxide and at times also minium and lead oxide. In 1952, the company began making high-speed grinding wheels, one of the first in Europe to do so. Today, Rhodius Schleifwerkzeuge GmbH is the largest manufacturer of cutting and grinding wheels in Germany, exporting to over 100 countries worldwide. Surprisingly enough, these very technical activities directly led to the company becoming involved in beverage production. For when Manfred Rhodius, company owner in the second generation, departed for New York to conclude contracts for his grinding tools in 1958, by complete coincidence he also made contact with Pepsi. By the time he returned to Germany, Manfred Rhodius had closed a contract with the Pepsi Bottling Group as the first franchisee in Germany commissioned with the filling of Pepsi-Cola and later also other products in the Pepsi range under license.

Rhodius brands also marketed since 1974

For many years the Rhodius company acted solely as a bottler of Pepsi brand products. It wasn't until 1974 that the Pepsi franchiser began filling its own mineral water and other soft drinks under the Rhodius umbrella brand. Tönnesmann claims, "This was exactly the right decision. We now have two strings to our bow in our beverage sector: our own brands plus license and contract filling."

An all-rounder

The company's own brand beverages chalks up around 30% of all filled units. Contract filling accounts for the remaining 70%. About 60% of the items filled under contract are Pepsi brand beverages. Particularly in this area of contract filling, Rhodius' legendary flexibility stands it in good stead. In this capacity, the bottling plant is able to fill a wide range of soft drinks plus alcoholic beverages, such as beer, wine, mixed wine beverages, and Prosecco – in various types of container, of course. Cans, non-refillable PET and PETcycle bottles, glass bottles, and kegs are all used in a multitude of variations. All told, there is hardly a product or container that Rhodius isn't able to fill and package. "This high degree of flexibility is what largely contributes to our present success," says Tönnesmann.

Looking ahead with Key and Power Point in cans

Extreme flexibility is not only limited to the area of contract filling, however. Rhodius' own brands are also available to the consumer in a wide range of different container types. The most recent campaign that speaks not only for the mineral water company's flexibility but also for its powers of creativity is the 'invention' of the brands Key and Power Point. Both are filled in cans and because they are both whey products, they are not subject to deposit laws. With its non-deposit products in cans, Rhodius has been able to gain both regional and national coverage on the German market sooner than expected. "The particularly rapid success of our new brand products in cans," says Tönnesmann, "has caused quite a stir in the mineral water industry nation wide."

No end to the number of awards

Success through flexibility and creativity is just one side of the coin for Rhodius. The other is that Rhodius can shine with a mineral water that has such high quality that it has won several awards. Rhodius mineral water is especially rich in magnesium, possibly prompting the DLG, for example, to award it with three gold medals in the categories Classic, Medium, and Naturell. The company also received the maximum three stars possible at the Superior Taste Award, an international competition ranking quality and taste. The German magazine Öko Test grades Rhodius mineral water "very good". At the same time expert sommeliers in the journal Alles zum Wein and Zenith International have confirmed that Rhodius Mineralwasser has the best characteristics to complement wine.

Among Rhodius' own brands, Rhodius mineral water has the largest share of sales at 80%, with 10% going to apple spritzer. The remaining 10% is shared by the classic soda pops, sports and energy drinks, and also Rhodius' Fructi brand fruit juice. As far as Rhodius mineral water is concerned, the medium variety is enjoying increasing popularity. The current distribution of sales percentages among the company's waters is as follows: 60% for Rhodius Medium, around 35% for Rhodius Classic, and approximately 5% for Rhodius Naturell.

Equally successful in both the retail and hospitality trades

In the main, Rhodius' own brands are distributed on a regional basis and are marketed within this region in the high price segment. Active sportsmen and women of all age groups form the target group. Brand products by Rhodius are enjoying an increasing popularity not only in the retail trade but also in the hospitality sector. For example, the sales volume for Rhodius mineral water delivered in 0.7-liter glass restaurant bottles is about 500,000. Says Tönnesmann, "Five years ago the number of 0.7-liter bottles sold to the hospitality trade was barely a fifth of this. We have also recorded a marked increase for the 0.25-liter restaurant bottle and within five years have managed to triple this figure to approximately five million units."

Keg encourages good relations with the hospitality trade

Rhodius' good relations with the hospitality trade will be promoted further by the installation of a new KHS keg line. Since the line was commissioned, kegs have replaced the bulk containers previously delivered by Rhodius to hospitality clients. "We have received nothing but positive feedback from hospitality businesses regarding the switchover," declares Tönnesmann. "They specially like the easy handling and the high level of hygienic safety that always comes with the keg."

In fact, there are many aspects in favor of racking soft drinks in kegs. Firstly, the hospitality trade is familiar with the keg from the brewing industry, a type of packaging that combines the advantage of taking up little space with easy handling and maximum hygiene. A second clear plus in favor of the keg in conjunction with soft drinks is that here a stainless steel cask is used that prevents the filled product from coming into contact with the surrounding air, as it is always sealed in a pressurized container both during and after the racking process. The keg is also impervious to light, tasteless, resistant to corrosion and impact, and allows the product to be stored for a very long period of time without any impact on the quality. In addition, not only does top-quality product come from every keg; this high quality is also maintained in the keg over a long time period of time. Regardless of whether the keg is emptied in two days or two weeks, restaurant customers are always given the best possible quality of beverage.

This creates one advantage after another – which is how PepsiCo Deutschland GmbH also sees it. Tönnesmann is enthusiastic, "Our new top-quality KHS keg line is considered a very positive addition by our licensing partner. The majority of our keg racking activities are currently focused on Pepsi brands."

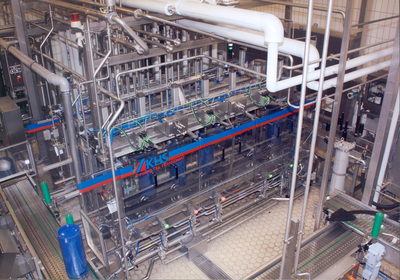

KHS keg line ready for operation in no time at all

The new KHS keg line was integrated into the bottling shop in practically no time at all. Tönnesmann states, "Within just three weeks the new line was ready for operation and had begun production. As usual our partnership with KHS was extremely cooperative; KHS worked hand in hand with our employees."

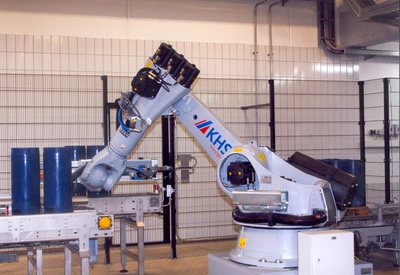

Versatile palletizing and depalletizing robot

The new keg line has capacity of 160 kegs per hour and processes 10 and 20-liter slim kegs. The first and last station on the new KHS keg line is the Innopal RK 6 palletizing and depalletizing robot. What's special about this 6-axis robot is that it is extremely versatile and able to navigate up to 25 target positions on 8 functional units. It can bear workloads of up to 240 kilograms.

Pallets of empty kegs are transported to the Innopal RK 6 by a pallet conveying segment. The empty kegs are centered before two of them are picked up by the robot. Once they have been turned, the Innopal RK 6 places the empty kegs on the conveying segment destined for the exterior keg washer. On their way to the washer, the system checks the keg fittings for the presence of protective caps. Because most kegs are returned without protective caps in place, an automatic cap stripper has not yet been included in the line; if necessary, the operating personnel remove any remaining caps from the fittings. If the number of kegs returned with caps should considerably increase in the future, suitable space has been left on the line to deal with this eventuality.

After the empty kegs have been removed from the pallet, the Innopal RK 6 takes care of pallet handling and transports the empty pallets to a designated parking station.

The robot additionally handles processing of the first freshly filled kegs as soon as they are discharged from the line. It first moves the empty pallets to the pallet conveying unit for full containers. The Innopal RK 6 then picks up two kegs at the same time – as it did during depalletizing – which are then turned through 180°. Next, the Innopal RK 6 conveys the kegs to the capper and labeler before depositing them on the full keg pallet.

The Innopal RK 6 is constantly aware of the current situation on the line. If, for example, the full keg section is becoming crowded, the robot will focus on palletizing full containers. If there are not enough empty kegs in the system, it will turn its attention to depalletizing empties. An intelligent logic controller sets priorities, thereby ensuring a continuous keg flow within the line and associated high system performance.

Fast and simple adaptation to new situations

If a changeover from 10 to 20-liter slim kegs (or vice verse) is scheduled, the Innopal RK 6 can be quickly adapted. Since the diameters of both 10 and 20-liter slim kegs are identical and only the heights of the two vary, the necessary changes can be made at the push of a button at the operator panel.

Keg exterior washing across several zones

Depalletized kegs are taken straight to the Innokeg Till AK 1 exterior keg washer. The exterior washing process is carried out over several zones. The kegs are pre-washed with caustic and mixed water to remove coarse soiling from the fitting area and the shoulder of the kegs. Main keg washing initially involves intensive caustic treatment that removes labels, among other things. They are then treated with mixed water. Just before the kegs leave the exterior washer, the last step in the cleaning program involves spraying them with fresh water.

Keg interior washing using the pulsating spray process

The next stop on the line for the kegs is the Innokeg Till TRANSOMAT 5/1 Duo. Both of the two washing and racking segments are equipped with one racking station and five active washing and sterilizing stations, plus one passive caustic soaking station.

All kegs are checked for residual pressure at the first Innokeg TRANSOMAT 5/1 Duo station or before the washing cycle starts. Any kegs failing the test are channeled out later. If they pass the test, remaining beverage is then blown out of each keg with sterile air. This way, any liquid present in the keg is removed through the ring channel. This is followed by pre-spraying with mixed water in order to rinse out coarse soiling from the keg, such as thickened beverage residue. The fact that the mixed water used is salvaged from the last hot water spray of the washing process helps to specifically save on water, wastewater, and energy. A pulsating spray process with caustic and acid is used for the main keg washing process. This produces optimum cleaning action inside the kegs and on the spears. This is followed by final rinsing with hot water to remove any remaining cleaning medium and by a blowout with steam to remove the hot water. In addition to removing residual liquid, this sterilizes the keg and displaces any residual oxygen, creating optimum conditions for the filling process.

DFC filling system for high precision filling and low carbon dioxide consumption

Rhodius specifically opted for the DFC (Direct Flow Control) filling system that stands for maximum filling accuracy and guaranteed high filling speeds. Direct control of the filling process by a regulator valve on the product feed makes the DFC filling process extremely precise. This regulated racking process also ensures best product quality in the keg. In addition to this, the consumption of carbon dioxide in the DFC filling system is reduced by up to 40% versus conventional filling setups. In turn, in the DFC filling process it is sufficient to pressurize the kegs to a pressure that is slightly above the degree of CO2 saturation.

Keg scales for maximum safety

After racking, kegs are transported to the keg scales. Any kegs that fail to satisfy the given criteria are rejected onto a separate lane. 'Good' kegs are sent on to the Innopal RK 6 that processes and palletizes the filled containers as mentioned above.

Nothing left to be desired

"With our new KHS keg technology we now have a keg racking and packaging system that leaves nothing to be desired," Tönnesmann proclaims happily. We are just as pleased with the exceptionally hygienic racking process that not only saves on product but also on carbon dioxide as we are with the innovative robot palletizing and depalletizing technology. The new line's great ease of operation is also extremely convincing. The container system previously in use here needed four people to operate it. Now we only need one."

Further proof of Rhodius' awareness of quality

Rhodius initially plans to fill approximately 200,000 kegs a year. Should the demand for soft drinks in kegs continue to increase, this figure could grow in the next few years. "In any case, investing in innovative KHS keg technology is further proof of Rhodius' awareness of quality," says Tönnesmann. "We are now also excellently prepared for future projects planned in the sector of contract keg racking."

The success story continues

Rhodius' policy is to react and behave differently from its competitors in certain areas and to thus continue the success story that began almost 200 years ago. As the motto goes, even declining markets don't just pose risks; they also offer plenty of opportunities. In this context, Tönnesmann admits that they already have a new innovation in the pipeline – one the mineral water industry can look forward to. And in the future it might also be worth them keeping an eye on what's going on in Burgbrohl …