Future-proof labeling: efficient and flexible

Not without good reason does KHS stand for top quality standards. We support our customers as their reliable partner from their initial inquiry for a product system to continued services following installation. This also holds true for one of the most important steps prior to completion of the overall production process: labeling. Our modular Innoket Neo system satisfies all requirements for high-quality container dressing.

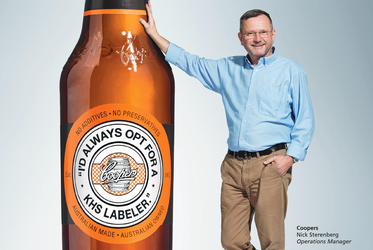

Individual consultancy is top priority at KHS, for we want that you only use tailor-made products and services in all areas of your filling and packaging operations. Labeling, too, is all about the details that can make a noticeable difference. Countless satisfied customers worldwide rely on high-quality labeling technology from KHS, for with it they know that they are placing their production processes in the experienced hands of experts who never lose sight of the big picture. We have the right system whatever the requirement in our extensive portfolio – and as your reliable partner are always on hand to provide support.

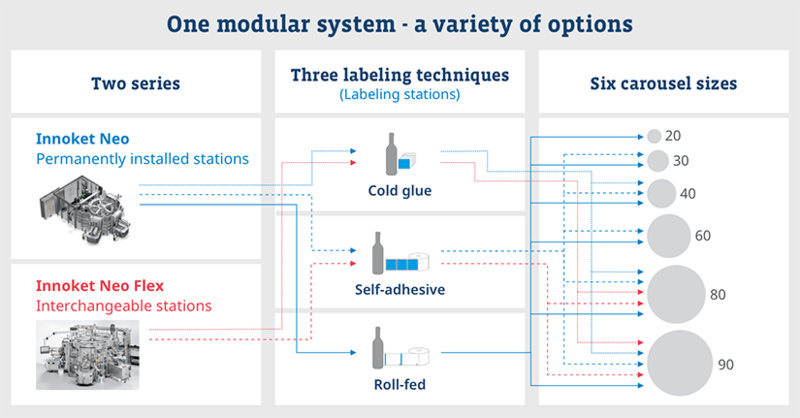

Wide range of options: KHS labeling technology at a glance

- Innoket Neo

Our modular system enables customers to configure their machinery as required. Whether the classic single labeling method or up to three different labeling techniques per machine, all this is possible with the Innoket Neo.

- Innoket Neo Flex

Our multifunctional labeler combines proven technology with a modular design to give you maximum flexibility, reliability and convenience. Its various modules can be easily replaced to meet changing requirements for future security.

- Cold glue labeling

With our KHS Innoket Neo you can exploit the full spectrum of cold glue labeling. Using the cold glue method, body, shoulder, neck and back labels in many different formats are efficiently and reliably applied to your containers.

- Roll-fed labeling

Our simple and efficient roll-fed labeling equipment is used for the wrap-around hot melt application of film or paper labels. The label material runs from the reel to the labeling station where it is cut to the exact length required by our optimized cutting system with self-sharpening cutters.

- Self-adhesive labeling

KHS’ powerful self-adhesive labeling station for glass and PET bottles and beverage cans is ideal for premium labeling tasks. Using this in combination with printed transparent film labels, for instance, you can give your containers a direct print or ‘no-label’ look and explore numerous design and marketing options for a strong brand image. The station can be used to label a whole variety of products from conical and cylindrical containers through PET and glass bottles to cans.

All-round service for top performance

In order to give our customers the best quality for their labels, we have set up a

KHS test center with its own label testing laboratory. This enables us to optimize any labeling process quickly and professionally. With our years of expertise we offer you all-round service – from materials testing through quality assessment and the specific setting of labeling parameters to fast solutions to problems caused by materials.

Another highlight is our targeted in-house development of high-quality consumables that cater for your specific individual requirements. For we urgently recommend that you go for high quality right from the start when sourcing consumable goods. It is essential that the label is precisely positioned at the designated place on the container for a perfect overall appearance. This is only possible when suitable glues and adhesives are used. With decades of experience to our name, we provide PETCYCLE®-certified adhesives specially developed for PET labels that support bottle recyclability and thus help to protect our environment in the long term.

„From glass through PET to cans, labeling technology from KHS provides great flexibility for future-proof applications.“