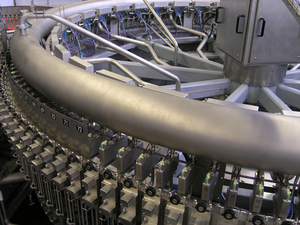

Innofill PET DVF PET filler

Flexible beverage filling for a wide range of requirements

Good to know

With the Innofill PET DVF you can expect a modern, highly professional filling system for the careful filling of beer, mixed beer drinks, and soft drinks in PET bottles. This machine enables you to fill products at up to 45,000 bottles per hour while ensuring maximum fill level accuracy. Each of our PET fillers is available as a single machine or monoblocked with a bottle rinser or a stretch blow molder.

Well thought out

All valve functions are pneumatically controlled for minimum maintenance and wear. You can additionally rely on exact fill levels based on our volumetric measurement using electromagnetic inductive flow meters that also help you to avoid product loss. In addition, all processing sequences are automated and all processes are documented and are reproducible for you at all times. We offer you the right system tailored to your requirements at all times.

Convincing

- Bottom-up filling for minimum oxygen pickup

- Warm filling at up to 16°C prevents condensation

- Volumetric filling method offers exact filling accuracy

Sustainable

- Eliminating the need for pre-evacuation saves you water and CO2.

- The hygienic design allows you to carry out sanitizing quickly and efficiently.

- Low-foam filling with exact amounts reduces your product loss

Good to know: with our platform system you can add modules to your machinery to allow you to flexibly process further beverage types or container sizes in the future. This means that you are all set up to meet constantly changing future market challenges today. Invest in the long term and benefit from efficient maintenance and an optimum supply of spare parts – for increased line availability.