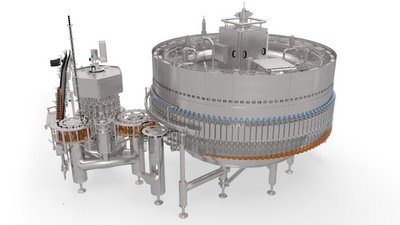

Innopro UCF process engineering

Optimum beverage preparation for sophisticated ultra-clean filling

Good to know

In the ultra-clean filling of your sensitive beverages the highest standards of hygiene apply when it comes to microbiological purity. Our Innopro UCF (ultra-clean filling) process engineering can provide you with a machine that easily satisfies these demands. Its many varied areas of application include pasteurization, buffering, and beverage-sterile, non-reinfective product control for optimum beverage preparation. At an extremely high output of up to 72,000 liters an hour Innopro UCF machines can process a broad range of beverages, from juice spritzers and mixed milk beverages through sport and health drinks to near-water beverages. The pH of your beverages must be less than 4.5 and the CO2 content between 4.5 and 6 grams per liter to ensure perfect UCF operation.

Well thought out

With its compact design this process system is extremely flexible thanks to the use of sophisticated process modules, making it perfectly adaptable to the specifications of each of your products. Simple operation and monitoring give it excellent transparency – despite the great complexity of the job on hand. The result is hygienically perfect beverages with a consistently high product quality. Innovative KHS process engineering – there's no better preparation process.

Convincing

- First-class beverage preparation for ultra-clean filling

- No interface problems as the perfectly compatible system components and process parameters are from a single source

- Optimized use of specifically adapted process technology results in sterile beverage preparation that is gentle to the product

Sustainable

- Reduce the amount of operator intervention thanks to uniform operating, visualization, and software systems

- Reduce your energy consumption through the perfectly coordinated layout of all system and process components

- The compact, skid-mounted machine design ensures a long process system service life